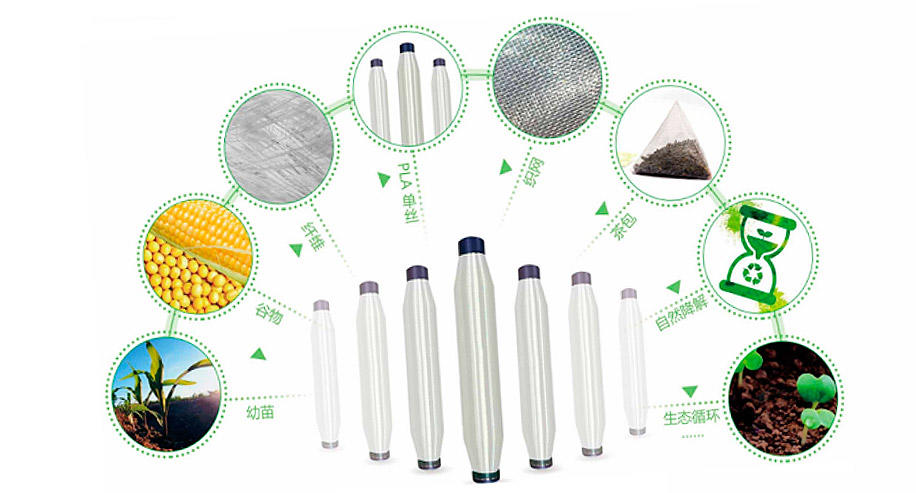

With a social mission of eco-friendly, recycle, sustainable development, we’ve developed this biodegradable PLA monofilament, its raw material can be extracted from soybean, corn, and sugarcane which are fully degradable under a certain condition. It has been applied in disposable food packaging ( tea bags ). Non-woven fabric, PET, and PA may possibly release hazardous substance after a long time of high-temperature brewing, in this respect, PLA has perfectly avoided the risk. On the other hand, it will be completely broken down by microorganisms under a certain condition, then generate CO2 and H2O which have zero contamination to the environment.

It can also be applied in the field of medical application, including IV infusion tubes, absorbable sutures ,disposable surgical gowns, sanitation supplies, etc.